About 7% of electricity generated in the U.S. is lost during transmission due to resistance of conductors. Superconductors are a unique class of materials which can conduct electricity with no resistance. This property can be advantageously used to transmit electricity over long distances with minimal losses, increase the power produced or reduced the power used by electric equipment as well as reduce the size and weight of electric equipment.

When produced in form of a thin film, superconducting wires can carry up to 200 times more current than conventional copper wires of the same cross section. We use a metal organic chemical vapor deposition (MOCVD) process to deposit high quality epitaxial superconducting layers on biaxially-textured nanometer scale buffers atop high-temperature resistant metal substrates.

Our focus is to improve the critical current performance of the superconducting wires especially in high magnetic fields. Microstructural defects responsible for decrease in critical current density with increasing film thickness are studied and appropriate modifications are implemented to the MOCVD process and materials.

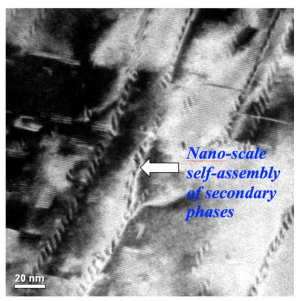

Additionally, nano-scale defects are introduced either in form of precipitates or self-assembly structures through appropriate compositional modification. These defects enable effective pinning of vortices resulting in higher current densities. Our goal is to achieve a critical current of 1000 A/cm in a 2.5 micron thick superconducting film, which is 50% better than the state-of-art today. Another goal is to achieve an isotropic critical current density with better than 50% retention at 77 K and 1 T, which is about 2 to 3 times better than the state-of-art today.

Research Faculty