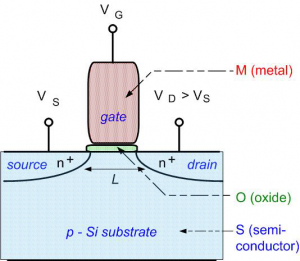

Over the last 40 years, the continued miniaturization of the silicon-based MOSFET (Metal-Oxide-Semiconductor Field-Effect-Transistor) has changed the way we live and work. Conceptually, this solid state electronic device is simple and elegant, but fabricating it at ever smaller dimensions has been a heroic challenge for the multi-billion dollar electronics industry. In state-of-the-art high performance logic circuits, the MOSFET’s smallest patterned dimension (L in the figure) is approaching 45 nm, making it one of the most ubiquitous nano devices in commercial use. Indeed, the oxide layer that is at the heart of the device’s operation is as thin as 2 nm.

In typical integrated circuits, the MOSFET acts as a simple switch: when a suitable voltage is applied to the gate, a current flows from source to drain. This concept is at the heart of binary digital electronics, and is used to fabricate the logic circuits of CPUs, DRAM and SRAM memory, and the pixels that comprise digital cameras, to name a few of its many uses. The reliability and integrity of the oxide layer, which enables the “field effect” and is thus at the heart of the device, has been a subject of intense interest since the invention of the MOSFET. As the oxide becomes progressively thinner (as is necessary for miniaturization), it becomes increasingly susceptible to damage mechanisms that can compromise its performance. Dr. Trombetta has been studying such damage mechanisms for many years, and is an expert in the area of MOS oxide damage, as well as the fabrication recipes necessary to mitigate that damage.

Dr. Trombetta’s research group recently obtained a grant from the US Air Force Office of Scientific Research (AFOSR) to study a particularly stubborn form of oxide damage: positive charging. Whether in common use in an integrated circuit or exposed to harsh environments (such as radiation), the MOSFET oxide sustains damage that can eventually destroy it. The group is tasked with developing ways to fabricate oxides that are less susceptible to such damage; these include special oxidation recipes and implantation of impurities designed to disrupt the electrochemical damage mechanisms that would otherwise operate. If the results are successful, they may help extend the life of Moore’s Law, and improve the reliability of integrated circuits.