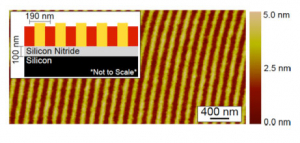

Next-generation nanofabrication requires economical lithographic processes that achieve sub-22 nm resolution with minimal pattern roughness. Current manufacturing practices are based on projection lithography with chemically-amplified (CA) photoresists; however, such "top-down" lithographic processes are approaching their intrinsic resolution limits, so alternative techniques like "bottom-up" block copolymer self-assembly are increasingly attractive. The physicochemical parameters that control imaging in top-down and bottom-up lithography are very different, but improving either technique requires accurate feedback for the structure of the "latent image." Our group uses novel X-Ray Diffraction techniques to acquire such feedback; data are then used to construct and validate physical models.

Solar cells based on conjugated polymers are a promising source of renewable energy: Manufacturing costs are low, and portable devices can be fabricated in light-weight, flexible, and durable modules. Current state-of-the-art devices are based on the bulk heterojunction design, an interpenetrating donor-acceptor network, and the reported power-conversion efficiencies (2-5%) are too low to compete with grid power. We developed a new methodology to systematically investigate the effects heterojunction architecture on device performance. Our methods decouple donor-acceptor interfacial area from domain size, periodicity, and purity. These parameters are all tunable and can be measured from actual devices with synchrotron scattering, enabling systematic investigation of structure-property-processing relationships in polymer solar cells.